Words and Images Joey Arguelles and Jaime Lagdameo

Editing The Kanto team

Editor’s Note: This Kanto Futurespace story is a student proposal from the De La Salle-College of Saint Benilde’s Architectural Design 7 Studio class. Below are the studio premise and course focus by mentor Ar. Enzo P. Belandres, followed by a proposed car-centric tower by architecture students Joey Arguelles and Jaime Lagdameo.

Premise

Manila’s urban fabric, long defined by its resilience, faces unprecedented challenges in the year 3000. Overpopulation, construction saturation, and urban blight have rendered conventional solutions obsolete, demanding visionary approaches to urban planning and architectural design. This design class, set in a speculative future, challenges students to imagine a “New Manila,” an elevated city built upon a mega-plate supported by mega-columns. This new urban layer aims to address density, sustainability, and adaptability, serving as a paradigm for vertical urbanism.

Course Focus

This studio explores the integration of advanced architectural methodologies to address the complexities of future urban environments. Students will design high-rise and super high-rise structures that adapt to a city in crisis, utilizing the mega-plate as a conceptual and structural strategy. Key methodologies include operative mapping and scenario-based design, enabling students to analyze, synthesize, and project speculative yet practical interventions.

The Megaplate

Imagine this: It’s the year 3000, and Manila has just completed the construction of The Megaplate– a towering platform that sits 1 kilometer above the current metropolis, built to address some of the city’s most pressing concerns and position the Philippines as a major trading hub in Asia.

The Megaplate was planned around pre-existing road networks owing to the continued bias towards car-centric policies that led to an excess of air and land-based cars. The question is: could technological advancements and the general allure still encourage people to start businesses within Manila City? Would there be a way to design for this future by implementing vertical planning?

Design Concept

To address the requirements of a car-centric tower, the proposed Track Tower developed four key areas based on predicted “scenarios”: Car Manufacturing, Races, Pulse Hub, and Scrapyard.

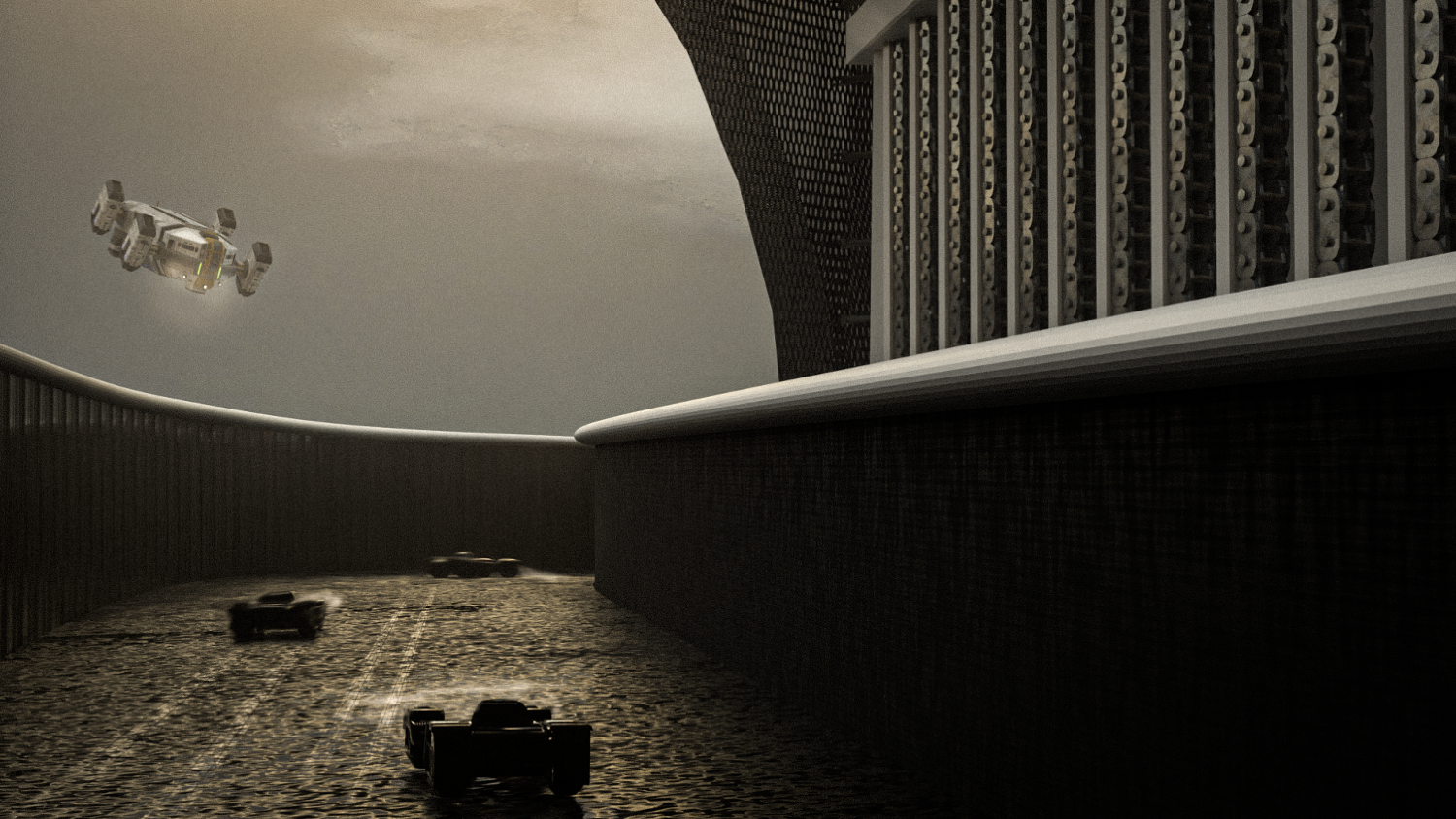

The imagined scenario for car manufacturing is that manufacturers develop a semi-autonomous process for land-based vehicles, which utilize nuclear power, requiring minimal human intervention. For racing, it is assumed that races incorporate higher elevation gains and more vertical movement. Cars used in these conceptual races exceed speeds of 300 mph, resulting in a more intense grand prix.

Pulse Hub will hold facilities that not only prepare racers by subjecting them to higher levels of g-force with the aid of specialized suits but also provide recovery for them through the use of stimulants and rehabilitation chambers. The scrapyard, on the other hand, is envisioned as a facility for repurposing race track and megaplate scrap to create new cars.

The initial form of the tower was based on the work of German-Venezuelan visual artist GEGO. Applying Spatial Mapping to the vertical layout within the GEGO tower helped us understand how each of the elements would interact and influence one another.

Facade Mapping allowed us to see how site conditions would affect the exterior of the structure and influenced the innovations required by the environment and end users, namely: (1) an operable Brise Soleil to increase and decrease the amount of direct sunlight hitting the facade of the tower; (2) second veiled facade layer to mitigate the impact of strong winds on the tower; and (3) the use of sound dampening technology already present in F1 races, and sound reflectors currently used in Japanese Expressways to address excessive noise.

We also incorporated a hypothetical structural system that works similarly to a car suspension, allowing for some movement of the race track since it could not remain structurally static for safety reasons.

Spatial and Facade Mapping allowed us to create a Tectonic Development to visualize any potential issues and create a more cohesive form out of the two. For our Brise Soleil, we overlapped voids and sun exposure to determine the optimal locations for placements and began to arrange each layer based on both the needs of each site.

Design Output

The first typical floorplate of the Megaplate is the main hub for vertical movement within the tower, housing the main ingress and egress points for both scaling and descending the tower.

The main race track floors were designed inside out; the interior core houses the main local and express elevators. Seating lines the outer perimeter of the floor plate, with a commercial area situated directly adjacent to the side with direct access to the race track. This doubles as a noise cancellation system, where an inherently noisy program is placed next to an already noisy space.

The pulse hub area is split into two; one more public area (the car museum and simulation chamber) and one more private for racers and the elite (the spa and g-force rehabilitation center).

Moving down the tower, the vehicle manufacturing space acts vertically linear. The design takes cues from existing vehicular manufacturing structures, but translates their processes vertically to maximize the height of the tower. There is also a connection point to the adjacent goods transportation mega column, which allows for direct access to Manila below.

The junk shop maximizes vertical circulation as opposed to large-scale horizontal movements. From here, processed materials are either moved to the vehicular manufacturing floors for car production or sold on the first typical floorplate.

No one knows for sure what’s in store for Manila in the year 3000. But if our car-centric visions suddenly turned out to be true and the country needs to implement vertical planning for a technologically advanced tower, our design will be ready and waiting. •