Introduction and interviews The Kanto team

Images Exhibitors, Patrick Kasingsing, and Hiblatech

Much ado about pineapple leaf waste? Possibly, if Hiblatech’s exhibition at Vestido Manila in Poblacion is your starting point. The sustainable fibers and fabrics company reveals the unglamorous math: the Philippines generates over 2.6 million tons of pineapple leaf waste each year, most of it burned after harvest. Hiblatech responds by redirecting the unsavory surplus into textile production, supplying the material that serves as a working prompt for 10 designers from fashion and industrial design in the show.

Works by Jasser Aguila, Chini Lichangco, Krete Manila, Razel Mari, Selena Placino, Edward Sibunga, Marc Carcillar, Modista by Jema Gamer, Yodel Pe, and Dee Javier engage directly with material behavior that departs from their usual palettes, resulting in mushroom-shaped lamps, sinuous wall dividers, and wearable pieces and accessories that emphasize surface and texture. As Hiblatech co-founder Tina Sabarre puts it, the material “behaves differently and asks to be handled differently,” nudging designers out of familiar workflows.

Before waste finds wonder in the designers’ hands, pineapple leaf waste moves through a standardized fiber-processing sequence. After harvest, discarded leaves are collected and mechanically stripped to extract long cellulose fibers from the plant material. These fibers are washed to remove sap and other residues, then dried and prepared for textile refinement. Depending on the application, the resulting fiber may be spun into yarn, formed into non-woven sheets, or blended with other fibers to meet the demands of furniture, fashion, product design, and beyond. One such output is Hiblafelt, a non-woven textile that sits within an established category while introducing a different material logic, designed to be built upon by its maker rather than treated as a finished surface.

The works on display at the January 22 exhibition follow earlier applications by designer Milo Naval’s OMO Furniture, ARTIFEKS, and artist-photographer Jo Ann Bitagcol; early experimentation has also revealed signals of acoustic and insulating potential, particularly in interior and spatial applications.

We caught up with Hiblatech co-founder Kristine Bañez for a deeper dive into the product and its intended direction. Industrial designers Jasser Aguila, Edward Sibunga, and Selena Placino join fashion designers Dee Javier and Marc Carcillar in chiming in on their experience working with the new material after the jump!

Chini Lichangco’s It’s Okay lamps

Marc Carcillar’s Half Full resin buttons

Hiblatech: Realizing Waste (not Wasted) Potential with Co-Founder Kristine Bañez

Hello, Kristine! Congratulations to you and Tina on the Hiblatech showcase! Was there a pivotal moment or memory that sparked Hiblatech’s creation? Why choose pineapple leaf waste, and how did community or ethical considerations shape that choice?

Kristine Bañez, co-founder of Hiblatech: I saw (Tito) Chuck Lazaro (Vice President at Asia Textile Mills) one afternoon in front of the house as I was arriving home. He is my next-door neighbor and a long-time family friend. I was just going to say hi, but in that quick hello, he mentioned he has a pineapple fiber-based fabric that he hopes to increase demand for, because it would mean providing additional livelihoods for pineapple farmers. I parked that as something to explore further with him, but a few weeks later, I met Tina (Sabarre) for coffee to catch up. And again, in what seemed like a random life update to her, I mentioned I had met Tito Chuck recently and would probably be exploring something on that product. Long story short, I introduced them to each other, and more discussions about ideas for what would be Hiblatech surfaced.

We didn’t really choose pineapple, technically speaking. As I shared, Tito Chuck was already working with it, and things “began” with exploring how to increase demand. The additional livelihood for farmers was an important aspect. If we can increase demand and provide an additional income source for farmers (farmers farm pineapples for the pineapple canning industry; the additional livelihood comes from after-harvest, when the waste leaves are collected and then fibers are extracted), that would be a win.

I see! And here we are today, with Hiblatech fibers used in fashion and industrial design at the exhibit. What other industries do you believe could benefit from the material? How are you working with partners to stress-test its potential and address challenges of scaling it for wider use?

Kristine Bañez: From our initial secondary research on the fiber properties, the fiber has sound and insulation properties as well as strength, which could be useful in many industries. For example, one of the designers (Krete Manila) exhibiting here has a lamp. But the body of the lamp is made with their version of concrete, incorporating fine pineapple leaf waste fiber trims. The original version of the lamp body without the fiber trims is also in the exhibit, but it is heavier than the version of concrete with the fiber trims. Aside from the fiber-trimmed version being lighter, it also passed the designer´s 76cm fall test (the material is dropped from a height of 76cm to see if it will crack when it hits/lands after the fall), like their original concrete version.

These are initial tests in material blends, which can have a wide range of applications. The speaker (by E/lou) exhibited here shows the acoustic properties and is very interesting because initially, we were looking at sound insulation. But in this particular collaboration, what we uncovered is sound projection, so to speak. Internally, we have our theories and ideas on what can be done with it based on our own secondary research. We try to find collaborators like the designers here who are willing to take on what could be a different kind of creative challenge, as well as what could also be a more tedious and longer process.

In working with materials, one often does not encounter challenges to one´s existing or “tested” processes, timing, etc. You´re not only changing the look, color, shape, etc., but you’ll likely be faced with a material that behaves differently from your “tried and tested”. Which means, if you want to change the shape, you might need to rethink how you sew this new material, how you mold it, how you manipulate it, etc. This is only step 1, so it is critical to find designers and manufacturers who are willing to test with us.

Another vital step is encouraging users (either businesses or individual consumers) to try the products. Because we can test and make, but if there is no willingness to use the product, scaling will be a challenge. Scaling can be a chicken-or-egg scenario. Will large manufacturers only be willing to R&D with us once they can see demand, or will they be willing to test as we build demand? Hard to say. The ideal scenario is that, after initial small-scale tests show promise, larger manufacturers are willing to collaborate on R&D at scale, so that when demand kicks in, supply is ready. One reason we are also sharing this more broadly is to find partners and collaborators.

Jasser Aguila’s Kabu lamps

Jasser Aguila’s Kabu lamps

And we hope that you do find more partners! Curious, for this exhibit, how much leaf waste material was actually recycled? And on a broader scale, what benchmarks or metrics are you using or developing to measure Hiblatech’s success and scalability?

Kristine Bañez: We are still working on impact numbers. In general, what we know is that approximately 9 kg of fiber can be extracted from 500 kg of waste leaves. What happens with pineapple waste leaves is that, instead of being left to decompose and release greenhouse gases (GHGs) to the atmosphere, the fiber is extracted and used to make these materials. A kilo of waste leaves releases an estimated equivalent of 2.03 kg of carbon dioxide (CO2).

Was there a Hiblatech application on display today that you personally found most unexpected

Kristine Bañez: We think each application has its own merit, primarily because the material is not something any industry has really worked with in the past. So, everyone likely had to challenge something about their “usual” to get to the final products we see today. From trying to use it as a speaker (when we initially were thinking of sound insulation), to figuring out how it interacts with light, to seeing how it can be cut, colored, molded, keep a certain shape, blend with existing materials, using it to “paint” and artwork, etc., these are all unexpected and inventive. We are grateful and greatly appreciate the willingness of our selected designers to take on the challenge with us.

To close, what do you hope visitors will take away after three days of engaging with Hiblatech? Beyond this exhibit, what programming or initiatives are you planning to encourage experimentation and wider adoption?

Kristine Bañez: We hope designers, creators, manufacturers, engineers, and the like are inspired to test these new materials either within their current processes and products or to develop new ones. We are continuously looking for partners and collaborators and would love to explore and connect. Also, these products are for sale. We hope that people will incorporate these products into their professional or personal spaces. That way, designers are also encouraged to experiment or create more with these new materials.

We are currently planning several workshops where we hope people can interact with the materials and be directly involved in the product-making process. Kits will also be available in the future so that, beyond the workshops, people can continue to create on their own.

Jema Gamer of Modista

Binakael wall art and Orkilap dress

Hiblafelt: Weaving Waste to Wonder

Hello and congratulations on your Hiblatech showcase! Could you introduce your product and how you utilized Hiblafelt?

Jasser Aguila, designer of Kabu lamps: My work is a sculptural lighting collection called Kabu Lamps, inspired by mushrooms and other organic forms. I used Hiblafelt as the main material, cutting it into strips, layering them by hand, and shaping them into soft, rounded forms. There was opportunity to bring about more depth or character to this already beautiful material. I thought of burning it. Just as we do with Filipino food, I borrowed flavors to add texture to the fabric. The process was very intuitive; I let the material guide the final shape, rather than forcing it into something too controlled.

Edward Sibunga (E/lou), designer of Piña sound panel: My product is a sound object. A sculptural panel that produces sound. Built with a thin composite of piña felt and a corrugated plastic sheet. This allowed sound to be projected without a visible source.

Selena Placino, designer of Ihawi divider: Ihawi is a room divider that combines subtle sound absorption with playful interaction. Crafted from Hiblatech’s dense, non-woven felt, it gently softens sound while filtering light. The panel’s gentle waves help soften and absorb sound throughout the space. Inspired by ihawan (grill) and the act of turning skewered food over a grill, the wooden rods allow the felt panels to rotate independently, enabling a dynamic play of light, shadow, and openness.

Marc Carcillar, designer of Fill in the Gap bucket hats, Half Full resin buttons, and Retain This Memory felt tapestry: Retain This Memory is a framed artwork made of Hiblatech’s 250 gsm felt, yarns, and dark gray woven fabric. To create the piece, the 250 gsm felt was individually blanket-stitched in Hiblatech’s woven fabric to form a still-life arrangement of flowers. Running stitches were added to enhance the background using the yarns.

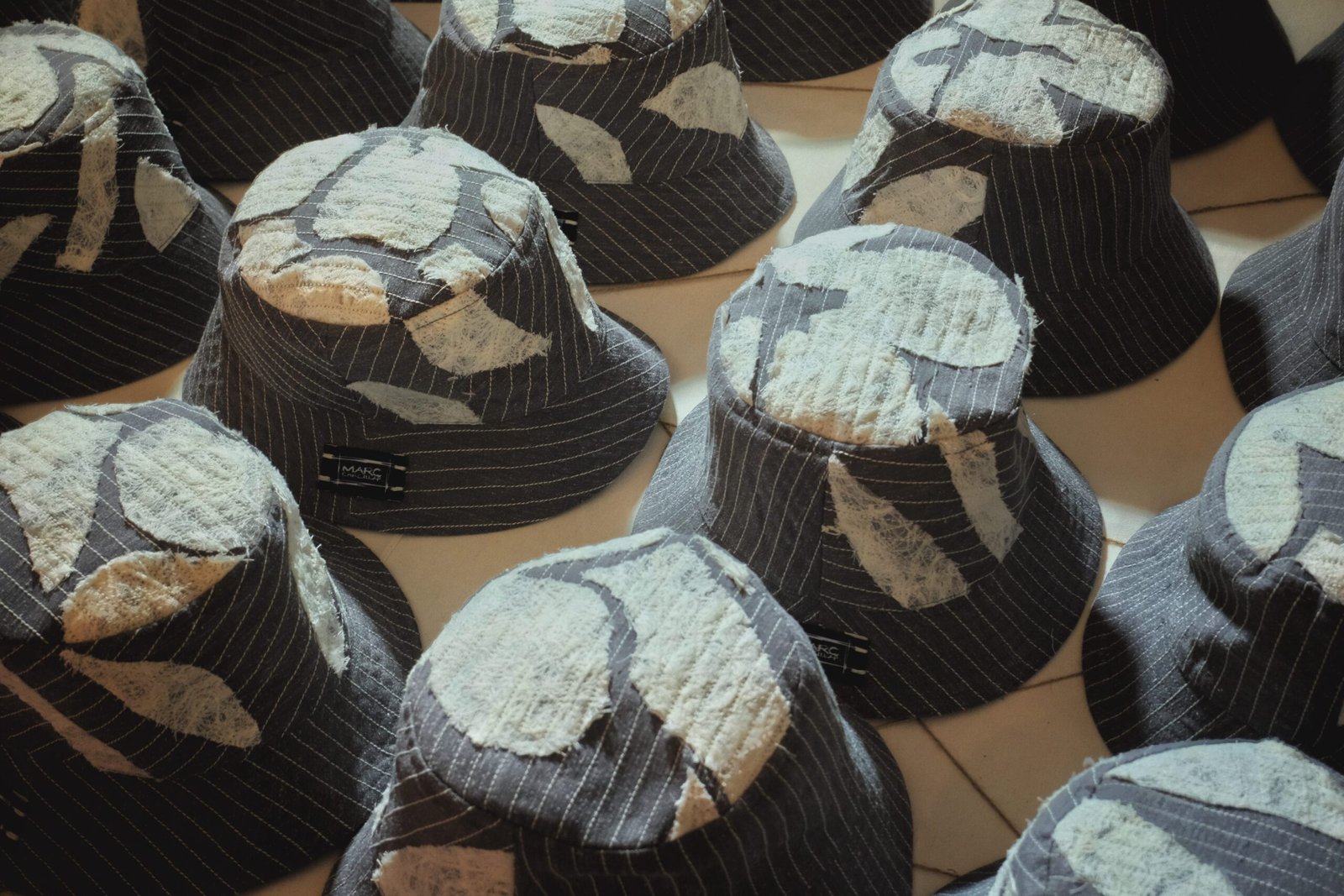

The Fill in the Gap bucket hat series is made from Hiblatech’s dark gray woven fabric, top-stitched with rugged threads, and embellished with tulle-laminated Hiblatech yarns.

The Half Full resin buttons are made from Hiblatech’s pineapple-waste leaf—raw and purified fiber, staple fiber, and fiber trims. Pineapple leaf waste is encapsulated in resin, producing buttons with distinct characters and textures.

Dee Javier, designer of On Her Sleeve artwork and Letticia brooch and tote bag: I made a brooch, tote bag, and a wall art display. I made floral shapes out of Hiblatech’s piña felt. The material possesses qualities that truly bring my designs to life.

Jasser Aguila’s Kabu lamps

You’ve had time to get intimate with Hiblafelt for the last few months. What aspects of working with the material felt most rewarding, and what challenges did you encounter?

Jasser Aguila: I like how responsive the material is. It reacts beautifully when it absorbs light, when you paint it, when you touch it, and especially when you burn it. It brings the piece to life in its own way. No two lamps will end up the same, which I really love.

Although there is a bit of a learning curve in knowing when to stop, especially when burning the material. Fire can easily overpower the fabric, so you really must be careful. It requires patience to watch over the fire, and you should also listen to what the material wants to do.

Edward Sibunga: The most rewarding part was discovering how piña felt could shift roles kasi it’s usually used to absorb sound. The contrast really opened new ways of using the material beyond its expected function.

The main challenge was control, since it wasn’t designed to produce sound in the first place. So, we needed to find ways to transmit sound vibrations.

Selena Placino: What I found most rewarding was the opportunity to work with a sustainable material. While experimenting with how to construct the panels, the process felt less wasteful because I knew the material itself was environmentally responsible. This gave me more confidence to explore and iterate. I also appreciated how Hiblatech, as a brand, gave us the freedom to explore and discover our own approaches to working with their materials and understanding its potential.

One of the main challenges was machine sewing the felt, as the material stretches and is difficult to control. In response, I shifted to techniques from my background in leather crafting, which proved more suitable, effective, and simpler for working with Hiblatech felt.

Marc Carcillar: Working with Hiblatech is rewarding because we can create pieces that go beyond conventional fashion items.

Dee Javier: It’s rewarding for me to know that using Hiblatech material means I’m supporting an ethical and sustainable local manufacturer.

Which qualities of Hiblafelt inspire you to explore further in your designs?

Jasser Aguila: I really like the rawness of the material. I think visually, and the way it feels is very familiar to us Filipinos. It’s lightweight, flexible, and imperfect in the best way. The way it holds texture and diffuses light opens up many possibilities for more experimental forms. I’m especially interested in pushing the limits of what it can do structurally while keeping that softness and warmth.

Edward Sibunga: The mix of cultural meaning and different material offerings. It’s deeply Filipino, tied to our history. At the same time, with the help of Hiblatech, it feels more open to experimentation since we have access na to fibers, felt, woven fabric, trimmings, etc.

Selena Placino: What inspires me most about Hiblatech is the brand’s openness to different possibilities and experimentation. This approach encourages anyone to explore the material beyond fixed applications.

I have yet to explore their other material offerings, such as woven fabric, as well as their twine and fiber materials, and how these could be further developed. These materials have potential for use in furniture, such as upholstery, as they pair well with natural materials like wood. I am also curious to explore their possibilities in combination with other materials and colors, opening new aesthetic and functional opportunities.

Marc Carcillar: The product’s flexibility (whether used as an embellishment or as the main material) and its varied textures are qualities I’m eager to explore. With more experience handling it, I’m confident I’ll learn new ways to apply it to my work and create new pieces.

Dee Javier: Fashion-wise, it’s challenging to utilize because of its texture and feel. But when I first saw these materials, I knew right away what I’d do with them. One thing that also excites me is the challenge. The texture. The organic feeling of the piña felt!

Selena Placino’s Ihawi divider

“ What inspires me most about Hiblatech is the brand’s openness to different possibilities and experimentation. This approach encourages anyone to explore the material beyond fixed applications.”

S E L E N A P L A C I N O

Marc Carcillar’s Fill in the Gap bucket hats and Half Full resin buttons

Beyond fashion or product design, where else do you imagine Hiblafelt could have impact as a material?

Jasser Aguila: I hope Hiblatech will be able to work with more designers so that there’s more creative minds that can play with this beautiful material. I see a lot of potential in interior spaces, tapestry, art, architectural wall panels, etc.

It’s the kind of material that invites people to slow down and look closer.

Edward Sibunga: Interior applications and other architectural elements. Maybe as panels, partitions or other surfaces with a clear cultural identity.

Selena Placino: It would be interesting to use the material as a finishing texture by mixing the fibers into wall paint or surface coatings to create a unique, tactile finish. I can also imagine it being used in architecture and interiors, especially for walls, partitions, or other surface applications.

Marc Carcillar: Since Hiblatech has just launched, I’m eager to see it flourish within the fashion and product design sectors.

Dee Javier: I can imagine Hiblatech in housing, maybe? Who knows? I think its organic component is good as a layer on ceilings and walls?

What’s next?

Hiblatech notes that the company’s production network connects 10 farm cooperatives and four fabrication partners, supporting 700+ individuals, with more than 60% of production costs directed toward labor and local development. As pineapple waste fiber and other next-generation materials edge closer to broader use, questions around consistency, output, and durability become the next priorities. New materials, after all, rarely slide neatly into existing systems, often requiring adjustments in process rather than surface treatment alone. But taken together, the works on view at Vestido The Studio offer a compelling start to a broader public conversation around the material. The journey is just beginning.

Hiblatech’s Design Exhibition at Vestido The Studio, Poblacion, Makati, opens to the public from January 23 to 25. •