Interview Patrick Kasingsing

Images KB Lucero

Hi, KB! Let’s build this interview on your background. How did you first get into civil engineering, and what drew you to the field?

KB Lucero: Leading up to the end of my high school years, I had considered pursuing fine arts education majoring in painting because it’s something I have been truly passionate about for as long as I can remember. However, my growing interest in math and science, along with my fandom of the American TV series Prison Break, led me to pursue civil engineering.

What’s the most structurally challenging project you’ve worked on, and how did you solve the key engineering hurdles?

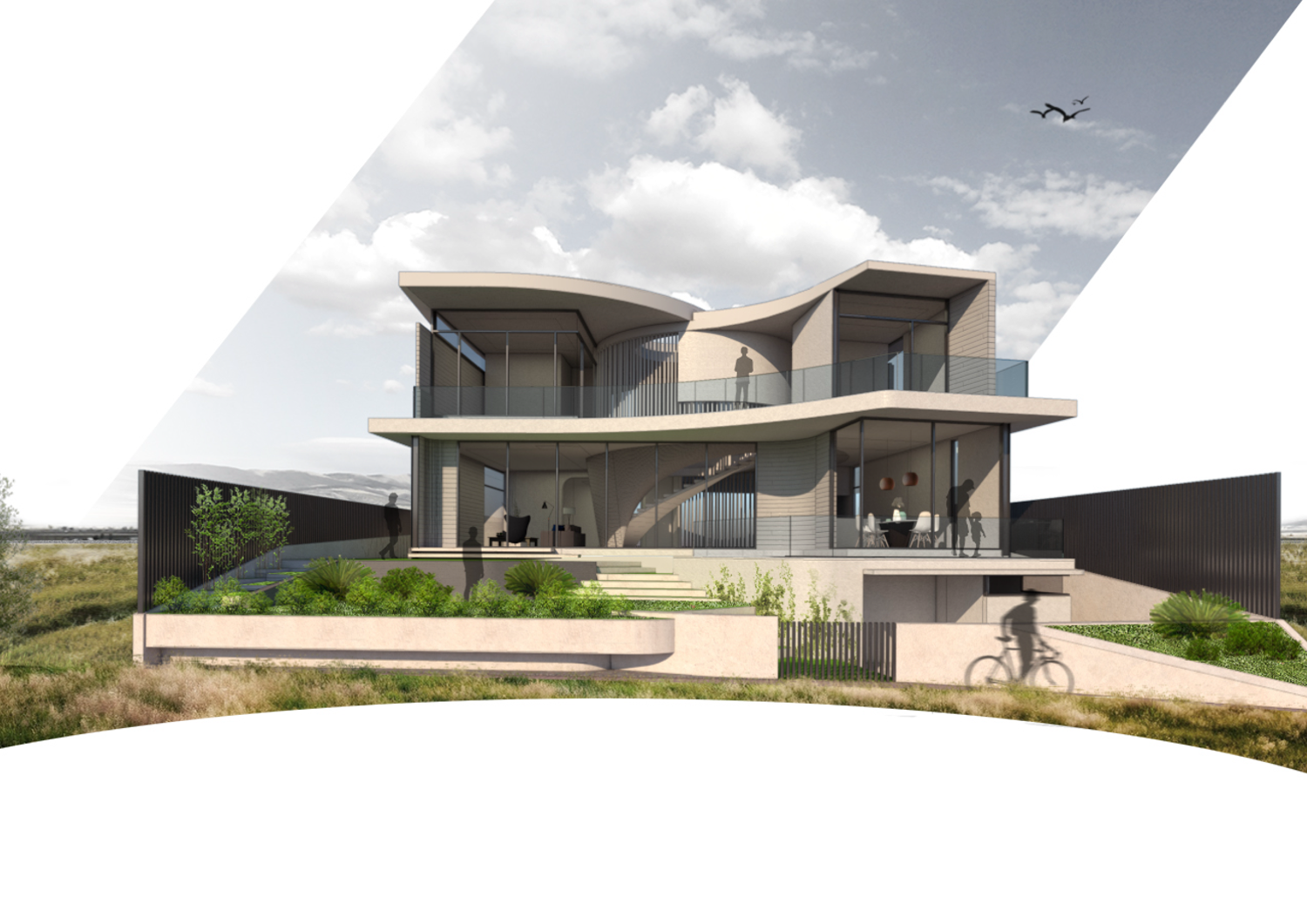

While most of the projects have its unique degrees of complexity and demand, first thing that comes to my mind is a residential project collaboration with Javier Design Studio Manila in 2018. Structure is just 10 meters away from an active fault line, sits on a cliff and is intended house valued and fragile art pieces.

Limited by the architectural intent, a major part of the structural system was designed to rely on two major frames similar to those of single pier plus overhanging beams of the LRT/MRT line or flyovers. These frames would support successive floor levels and were designed to withstand earthquakes and typhoons. Managing the of load path, negotiating for lighter materials, and collaborating closely with other trades were some of the major key factors in successfully executing this type of structure.

Scout Hall by ZUBU Design Associates

Architects often push for bold designs that challenge engineering norms. How do you balance these creative ambitions with the practical needs of structural safety?

I can’t stress this enough: Client expectation management is crucial. Stakeholders need to understand what the engineering parameters entail. The culprits behind the skyrocketing project costs and larger structural member sizes are, in most cases, the building’s classification, the proximity of the structure to an active fault line, irregular building shapes, soft soils, heavy architectural materials, and so on.

Let’s get into some field-specific questions. What’s a common misconception people have about what makes a structure “difficult” to build?

Designing and building a structure with limited number of columns.

How about engineering principles? What’s a fundamental thing that architects or clients often overlook but makes all the difference in execution?

Earthquake force does not only depend on ground acceleration; it is also based on the inertial mass of the building. This means that if your structure uses heavy materials and has high live loads, the earthquake force increases, resulting in higher design requirements for the structural members.

Is there something that looks easy in construction but is actually a nightmare to engineer?

I have not seen anything that looks easy in construction but one of the closest tasks might be the retrofitting of structural members using carbon fiber-reinforced polymer (CFRP). It may seem like workers are just applying resin and putting band-aids on the members, but behind all this, calculating the required number of CFRP plies to install on site is quite a bit of work.

Can you share an example of a project where your work felt more like art than engineering?

The Jenga House of Javier Design Studio Manila. House was intended to be bare, highlighting the complexity of the structural components.

Are there any new materials or technologies that excite you right now for solving engineering challenges?

Artificial Intelligence. I am currently in the process of further automating my workflow and developing new programs for computation with the help of AI.

What’s the most counterintuitive thing about structural integrity that people might not realize?

Concrete mix. The minimum threshold set by the code for frame structures is 3000 psi. Trial mixes on site often only achieve around 2000 psi or less, which is non-compliant for major structural members. While adding more water to the concrete mix seems to improve its workability, it often results in lower strength later on due to higher water content.

If accessibility and project budget are not significant issues, I would recommend acquiring a design mix from reliable batching plants near the site, as they conform to the correct concrete mix specifications and can assist with quality assurance monitoring.

Time for a few fun questions! Looking back at your career, is there a specific project or moment that made you especially proud of the engineering complexity involved?

I don’t think I can choose, all of them make me proud. They are all special in their own terms.

How do you unwind from the stress of working on high-stakes builds?

I listen to some of my favorite records, paint, draw, read, photograph the streets of metro and stare mindlessly at the sunset.

Paintings by KB Lucero

Do you find yourself analyzing structures in everyday life, like while traveling or walking around? What’s something most people wouldn’t notice?

Yes. Analyzing load paths, checking materiality, and connections and asking myself how I would do it differently.

If you weren’t a civil engineer, what would you be doing instead?

A visual artist. I’d be painting all day. Every day. •